|

DATADRIVE Series AC Motor Speed Control Devices |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Easy to use DataDrive motor drives are the best choice for all AC motor control applications..

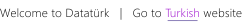

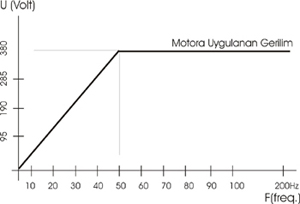

Datadrive AC Motor Drivers; 3 Phase is a modern speed controller that operates with IPM-SPWM technique which can set the speed of the motor to the desired value from the zero with the high starting torque. It is a new generation motor speed control device which is designed according to the network conditions and facilitated and can adjust the values of the user which constitutes 80% of all driver applications such as engine motor maximum speed, acceleration time, deceleration time and braking time without battling the user with complex technologies. AC Drives It is used in a wide range of industrial applications. Constant speed is not suitable for all operations in all conditions, speed setting must be used in all applications required. For example;

In the case of familiar tools such as food mixers or electric drillers, or in more powerful versions, the pump speed must be adjusted to control the flow of water and industrial chemicals to ensure airflow regulation in large heating and air conditioning systems.

However, variable-speed AC drives are often used in more complex and challenging environments, such as water and wastewater processing, paper mills, tunnel drilling, oil drilling platforms, or mining.

With AC drives; normal operation also controls the stress of the system, and saves energy when performing a potential speed control.

Use of smaller fuses and supply links and reduction of peak loads on the electrical network by reducing currents drawn by the mains during start-up demolition and shutdown Kalkış ve duruşlarda mekanik şok'un azaltılması Speed adjustment as control tool Acceleration control, Different operation speed for each operation, Allowing slow operation for installation purposes, Adjusting the production speed, Controlling torque or tension

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Using AC drives to save energy In the most commonly used fan and pump applications, energy savings of between 20% and 50% are achieved. For example; you can drive the fan with a fixed-speed motor, use a damper to limit the output airflow, or arrange the airflow by controlling the engine speed. Which of you is more efficient. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Advanced Technology Product SPWM Modulation / IPM Module Power Stage Compatible with our network conditions Easy commissioning and use Up to 50% energy savings Reduced noise levels Rational initial parameters Your application's load conditions and ambient temperature are two of the most important factors that influence the determination of the correct driver power. If load conditions require sudden peak currents, you need to select the drive power on the motor label. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Starting Torque Variable Torque / Constant Torque Overloadability 40*C, 45*C, 50*C Ambient temperature Metal Body Cooling Physical Dimension |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Switching Frequency DATADRIVE AC Motor speed controllers are designed using the latest technology in terms of software and hardware. The motor is protected against overload and overheating. The device generates a signal in sinusoidal form with PWM (Pulse Wide-Modulation) Pulse Width Modulation. With the 8KHz switching frequency, the motor is operated in silence. Multiple motors can be connected to the output of the unit. The programming menu is built in a simple structure that the user can easily understand.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The DATADRIVE VFD Series is available in AC motors for a wide range of applications requiring speed adjustment. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Phase|220VAC|Motor Drivers

Three Phase |380VAC| Motor Driver

Document | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||